CEDEX Track Box

CEDEX, Madrid/Spain

Scope

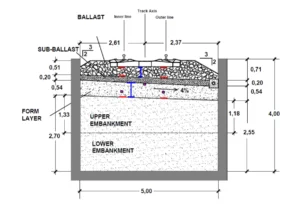

EDEX Track Box is a testing facility mainly developed for studying the geotechnical behavior of the railway infrastructure, composed by the track bed layers (ballast, sub-ballast, form layer, prepared subgrade) and the embankment. The facility allows testing models at 1:1 scale. The tests performed make it possible:

- Analysis of short and long term behaviour of the components of railway tracks submitted to any kind of train traffic,

- Determination of the response to innovations to be implemented in railway tracks,

- Data collection for calibration of 3D numerical models

Specifications

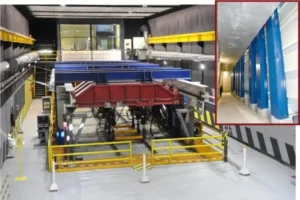

The CEDEX Track Box (CTB) is a 21 m long, 5 m wide and 4 m deep facility mainly for testing at 1:1 scale, complete railway track sections of conventional and high speed lines for passenger, freight and mixed traffics, at speeds up to 400 km/h. This facility includes in its design the execution of the railway substructure which covers the sub-ballast and form the layers and the embankment zones.

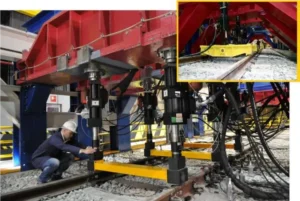

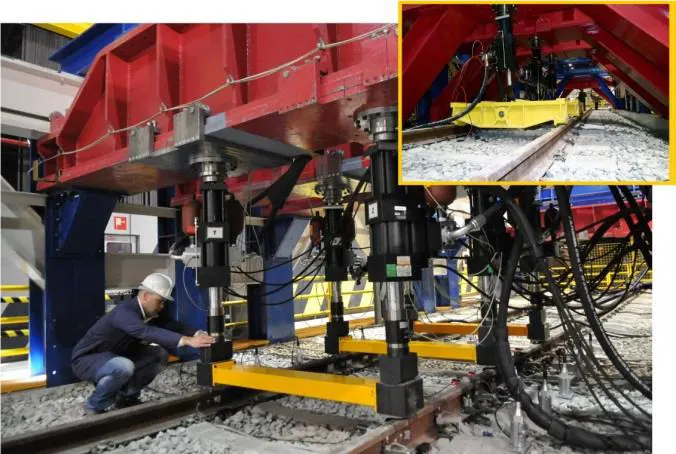

The CTB length it is divided into three zones, each of one can be used for a different railway track design section. The reproduction of the effect of the approaching, passing-by and going away of a train in a test cross-section, as it occurs in a real track section, is performed by application of loads, adequately unphased, via three pairs of servohydraulic actuators (maximum load of 250 kN at a frequency of 50 Hz). These actuators are placed on each rail at 1.5 m longitudinal separation. Its principal advantage is the possibility of performing fatigue tests in a fast way as in one working week, the effect of the passing-by of trains during a year in a real section can be modelled.

The tests that can be performed in CTB can have the following features:

- Tests with passenger and freight trains.

- Tests with static loads to determine track stiffness.

- Tests with quasi -static loads to simulate the pass-by of trains at speeds up to 420 km/h.

- Tests with dynamic loads to simulate the effects induced by track irregularities.

- Test to determine the fatigue behaviour of any track component (mainly, fastening system, ballast, subballast) by the simulation of pass-by of millions of axle trains.

- Tests to reproduce the effect of tamping operations on ballast degradation.

- Tests on vibration propagation.

- Tests to determine the lateral and longitudinal track resistance.

| Facility Details | |

|---|---|

| Name | CEDEX Track Box |

| Short Name | CTB |

| Owner | CEDEX |

| Location | Madrid/Spain |

| Website | Click Here to Visit Site |

| Contact | jose.estaire@cedex.es |

| Head of facility | José Estaire |

| Construction year | 2004 |