GEOTECHNICAL CENTRIFUGE

University Gustave Eiffel Nantes', Bouguenais / France

Scope

The Centrif-UGE is devoted to physical modelling in geotechnics.

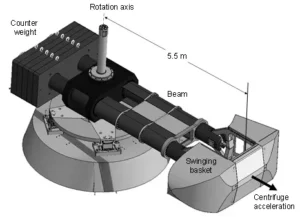

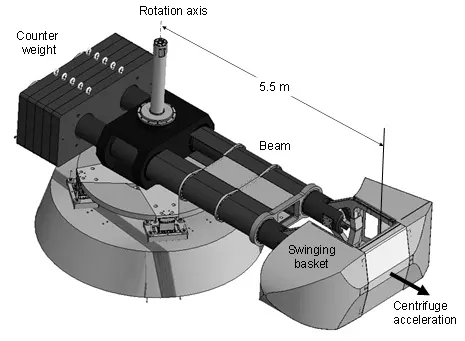

By increasing the centrifuge forces applied on a small scale model of a geotechnical work, the stress field existing on full scale (prototype) geotechnical work is reproduced. The model is installed in the Centrif-UGE’s basket (~1.5m3 of volume).

A set of scaling laws have been established (e.g. Garnier et al., 2007, doi.org/10.1680/ijpmg.2007.070301) for different applications.

The Centrif-UGE is versatile and offers a large domain of applications, concerning mainly soil-structure interaction (SSI):

- Piles, monopiles, piles group effect, helical piles under vertical/horizontal monotonic/cyclic loading;

- Off-shore anchoring systems for Oil & Gas or Marine Renewable Energy;

- Shallow foundations (e.g. in slope vicinity);

- Soft soils reinforced with vertical rigid inclusions;

- Construction of adjacent embankments on soft soils ; Reinforced earth structures (soil-nailed wall; geosynthetic layers)

- Tunnels: effect of excavation on surface settlement;

- Unsaturated soils;

- Ground vibration isolation;

- Cantilever wall;

- Seismic loading, soil liquefaction (not detailed in this document);

- Macrogravity testing of medical apparatus or aeronautical devices

Specifications

| Connections to the on-board scale model | |

|---|---|

| Electric, low-voltage rotary contact slip rings | 101 |

| Rotary contact connector power | 2A and 160A |

| Optical rotary contact connector and optical fibre | |

| Rotary joints | water, compressed air, hydraulic |

| Digital cameras and image processing | |

| Computer Network | |

| Facility Details | |

|---|---|

| Name | Geotechnical Centrifuge of the University Gustave Eiffel |

| Short Name | Centrif-UGE |

| Owner | University Gustave Eiffel |

| Location | Uni Eiffel Nantes’ Campus (Bouguenais/France) |

| Website | Click Here to View Website |

| Contact | centrif-nantes@univ-eiffel.fr |

| Head of facility | Matthieu Blanc |

| Construction year | 1985 |

| Associated Equipments | |

|---|---|

| Unidirectional earthquake simulator | |

| Four-axis remote operating robot system | |

| Miniature geotechnical investigation tools penetrometer, pressure meter, cane test, T-Bar) | |

| Hydraulic and electric servo actuators | |

| Sensors set (~230) acquisition chains | |

| Mobile pluviation hopper and consolidometers for test massif preparation | |

| Transparent face containers | |

| Roll-motion simulator | |

| Mobile tray for investigating the load transfer behavior towards rigid inclusions | |

| In-flight saturation |

Other relevant information

The Centrif-UGE is programmed week per week, one week corresponding to one research project. This allows to install the devices in the centrifuge (small scale model, loading systems, instrumentation connection,…).

The duration of one test varies a lot between few seconds for a seismic shot and few days for thick clay models.

Depending on the complexity of the expected tests, the design phase requires more or less time. Usually, a minimum delay of 6 months is required for scheduling the test.

The four other teams equipped with a geo-centrifuge are the people who do the same job than us. So easy connection is possible for complementary tests.